The Precision Craft of Diecasting: Revolutionizing Manufacturing

The Precision Craft of Diecasting: Revolutionizing Manufacturing

Blog Article

Diecasting plays a crucial role that is used in manufacturing today, and plays an integral role in creating intricate metal components with accuracy and efficiency. The process involves pushing the molten metal with high pressure into a mold cavity, which results in components that have exceptional dimensional accuracy and high finish on the surface. When industries change and demands for quality components rises, diecasting has continued to prove its value particularly in areas that need mass production of intricate parts. This article explores the diecasting process it's advantages, the benefits of diecasting, materials choices, and its extensive application across a variety of industries.

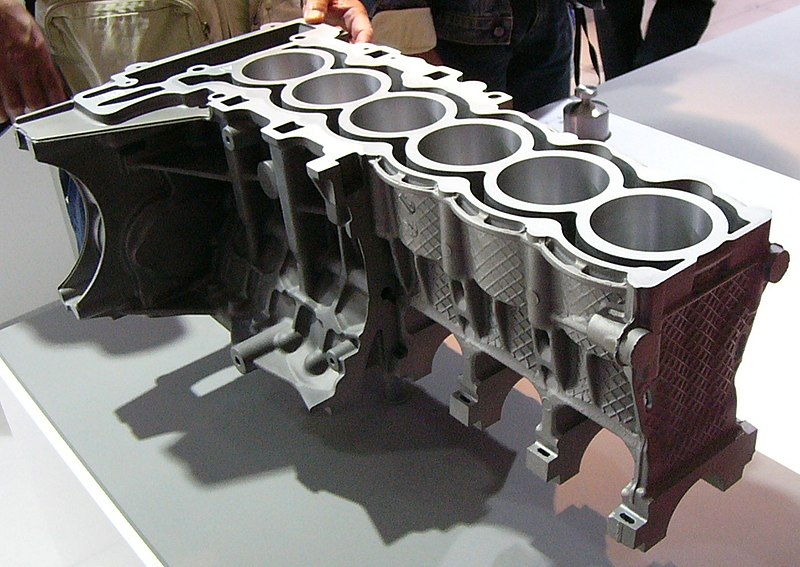

In the heart of diecasting is the usage of molds, also referred to as dies. Dies are created using high-quality steel that can withstand the extreme conditions of making. The dies are designed with precision, often incorporating elaborate details and precise tolerances in order to guarantee the accuracy of the final product. When diecasting is performed, molten metal-commonly aluminum, zinc, magnesium, or copper-is introduced into dies with extremely high pressures. This quick injection and subsequent the process of solidification results in parts with exceptional dimensional stability, as well as a flawless surface finish. This reduces the need for further cutting or polishing. The preciseness of the dies allows for the production of geometries with complex shapes that could be difficult or impossible to attain using conventional manufacturing processes.

One of the main benefits of diecasting is its efficacy in mass production. Once the dies are fabricated, they can be used to create thousands of identical components that have minimal variations. This degree of precision is essential for industries where large numbers of identical components. Additionally, diecasting is known as a material that is efficient. Diecasting produces minimal pollution, since excess metal is re-usable during subsequent casting cycles. It not only lowers cost of materials but also helps to promote sustainable manufacturing by reducing the use of resources and reducing waste. A combination of production speed, precision, and material efficiency makes diecasting a desirable option that manufacturers are looking to enhance their processes for production.

Diecasting can also produce products with exceptional mechanical characteristics. The rapid cooling of the melting metal in the casting process creates a fine-grain structure, enhancing the toughness and endurance of the finished product. This makes diecast components particularly appropriate for uses that require high performance and reliability. In the automotive industry they are employed for transmissions, engines, and structural elements. the strength-to-weight ratio is crucial for safety and vehicle efficiency. Similarly, in aerospace diecast elements contribute to the development of lighter but strong structures, crucial for optimizing the efficiency of fuel and performance. To acquire extra details please check this site out

The diecasting material used have a significant role to play in the final properties and performance of the final product. Aluminum is one of the most widely used components because of its superior strength-to-weight ratio, corrosion resistance, and good thermal and electrical conductivity. Zinc alloys are also well-known, offering high toughness, ductility and the capacity to make parts with intricate specifics. Magnesium alloys benefit from the advantages of being the lightest structure metal. They are the ideal choice for any application where weight reduction is critical. Copper alloys, while less common, are used because of their outstanding electro-conductive properties and corrosion resistance. The selection of the material is based upon the specifications of the job, such as mechanical properties, physical conditions in the environment, and also cost considerations.

Diecasting is a crucial manufacturing method that permits the production of high-precision, premium metal components for an array of different industries. Its capability to make intricate designs with high-quality tolerances and flawless finishes can be used in applications which require precise details as well as consistent high-quality. Its efficiency and effectiveness as well as its cost-effectiveness diecasting add to its value as it supports mass production while keeping high quality standards. As technology advances and the demand for reliable, lightweight, and durable components increases, diecasting will remain the foundation of modern manufacturing. It drives the development of new technologies and a higher level of production.